Control strategy of the wind speed in the hood of the laboratory variable air volume exhaust hood

Abstract:With the continuous development of science and technology of our country, as a scientific experiment technology theory is also increasing popularity and improvement, scientific experiment concept security begin popular awareness for experimental safety continues to improve, for the exhaust hood requirements are also constantly improving. Whether it is professional scientific research personnel, or into the science school students, not a strange place and laboratory, however, during the process of the experiment may be some harmful gases, so how to protect the experimental personnel in our laboratories are not subject to these harmful gas harm, is the primary problem we exhaust cabinet researchers. The basic principle is to control the speed, so as to control the air pollution and emissions collection. I mainly elaborate the domestic several types of the exhaust fan and its working principle, and put forward some design optimization suggestions.

We all know that if we want to control the pollution, we need to control the wind speed of the hood. But in practice, there are many in our laboratory will disturb the airflow interference fume hood face velocity, the flow causes very much, the most common reason: doors and windows of the switch, the movement of people, indoor air supply system etc.. Although our exhaust cabinet has been able to control most of the pollution of gas, but because of the existence of some other interference, the control effect is still restricted. So how can we improve the control performance of the exhaust gas tank to the polluted gas? The following will be analyzed one by one.

The significance of controlling the wind speed of the hood surface of variable air volume exhaust hood

The cost of air conditioning system in our laboratory is generally 3-6 times the cost of general building air conditioning system. Its operating costs are also relatively high. At present, in order to ensure that the experiment can completely collect reasonable harmful gas emissions, we generally use the fresh air system, but its cost is very high and the use of the past, and the variable air volume ventilation system is an effective way to reduce the cost of our air conditioning system and use cost.

In the past, the air volume of the exhaust fan in the air conditioning system of constant air volume is quantitative, and its operation consumption is also quantitative. The door size change does not change its exhaust volume size. While VAV ventilation system can according to the change of door face velocity change. For example, the minimum wind speed is 0.5m/s, then when the door opened in 1/4 when the face velocity is increased to 2m/s, when the door is fully open, the face velocity can be immediately increased to 10m/s. But the high face velocity may lead to dramatic changes in our airflow over the test-bed, and then it can lead to air pollution in the cabinet at a gathering, we may blow out the experimental flame failure experiment results. But when the hood surface wind speed is not enough, the pollution of the gas can not be ruled out, it will lead to the risk of inhalation of harmful gases. Therefore, the exhaust system must be adjusted according to the specific experiments on the test bench. The cabinet door size changes the face velocity, and can greatly reduce our laboratory exhaust system in a certain range of energy consumption. VAV ventilation system than quantitative exhaust system can save energy about twenty percent, for example, a laboratory needs ventilation 6~60ACH, if the use of variable air volume ventilation system, can save considerable energy. So our modern laboratory should be widely used in the exhaust system of variable air volume.

Wind speed control principle of the hood surface of variable air volume exhaust hood

To select the row of wind cabinet with different specifications according to the experimental nature of the laboratory, the current widespread use of the British Standard (BS7258) specified in the different experimental requirements of face velocity standard: conventional recommendation table as shown in table 1:

face velocity(m/s) Experimental type of exhaust fan

Min0.7 Experimental operation with radioactive material

Min0.5 Routine experimental operation

Min0.2 Chemical storage operation

British Standard (BS7258) conventional recommendation form

Can be seen from the table, chemical storage experiment for the face velocity minimum, the minimum is 0.2m/s, if the face velocity is too large may cause chemical changes, is not easy to store operation. The minimum cover surface wind speed of the conventional experimental operation is 0.5m/s, this requirement can be completed. With the experimental operation of radioactive material for the requirements of the cover surface wind speed is relatively high, the minimum to reach 0.7m/s. The above experimental types of exhaust cabinets are specially made out of. The use of this kind of quantitative exhaust cabinet, causing the laboratory's classification is too much, the utilization rate of the laboratory is reduced. The air exhaust system with variable wind speed control can meet the different nature of the experimental operation requirements. Change the size of the sliding door can adjust the hood face velocity. To minimize the possibility of harmful gas escaping from the ventilation range of the exhaust hood, and to ensure the safety of the personnel on the test bench.

Introduction of air flow control in laboratory

3.1 Laboratory air flow control mode

After 40 years of laboratory airflow control technology of continuous development and improvement, has been from the original CAV system into VAV, bistable system, this stage has been developing into adaptive control system, which is to protect the safety of laboratory personnel, and more energy efficient, more stability control system.

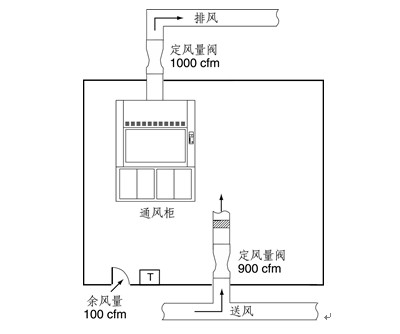

Constant air volume control(CV)

CV was born in 1940, the system is fixed to send air is not with the ventilation cabinet window opening adjustment and change. System characteristics: control is very simple, poor safety performance, adaptability is not strong, and the energy consumption is amazing, can not meet the requirements of complex experiments. The structure diagram is shown in figure 1.

figure 1.

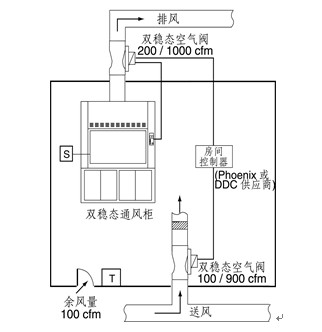

bistable control

Constant air volume (CV) control system can not meet the needs of the exhaust air, the safety and energy consumption of the defects of people's attention, the bistable control also came into being. This system is relatively constant wind control has been improved, there is a choice between a high wind, low volume, such as exhaust air needs of small experiments or in the laboratory at night dormant select low volume gear operation. The energy consumption of the exhaust system is reduced, but the system is similar to the constant air volume system, the system has poor anti-interference ability, and the adaptability is not strong. Schematic diagram of the structure as shown in figure 2.

2

variable air volume controlWith the development of control technology, variable air volume control system has been developed. The wind speed control method is generally arranged in the exhaust air outlet of a wind speed detection instrument (such as a hot ball wind speed detector, hot wire detector) to detect between the air. The detected face velocity controller incoming exhaust system, control power or motor exhaust air exhaust door according to the requirements of the wind. Strong adaptability to reduce energy consumption, but the valve control accuracy and speed of the requirements of high.

adaptive control (UBC)

By installing a magnet distance detector or variable resistor in the door to determine the exhaust cabinet door height, the exhaust volume according to our actual height calculated by the door. The hood surface wind speed of the exhaust hood is generally calculated by the formula of Q/A= Q/bh v=.

airflow control of ventilation cabinet

ventilation cabinet air flow control using displacement sensing + precision air volume control valve control system. You need to install a hood face velocity measuring device in the air outlet edge can be, but this is usually the wind speed detection Maple air outlet, the advantage will appear cover surface wind speed and wind speed detection test bench without using direct wind speed measurement, so the control method still has some shortcomings, for the high wind speed standard laboratory not recommended.

Four, the end of the language

With the security of people's increasing awareness of the continuous development of science and technology, the research on some special properties of chemicals, requires us to control the performance of modern laboratory ventilation and exhaust system improvement. Covering wind speed is a key concern and research. Directly related to the safety of a laboratory experiment, and the impact of the experimental economic expenses of the entire experiment. We used only by detecting the face velocity to determine the size of a fume hood performance is good or bad, but this method is not scientific, the different nature of the experiment for the face velocity demand is different, the high wind speed for chemical storage operation big slope slide, so we need to adjust measures to local conditions, according to the actual demand to adjust face velocity. For example, we have a standard modern laboratory needs to test the experimental personnel to judge the respiratory concentration of this exhaust cabinet quality. Therefore, it should be widely popularized variable air volume exhaust cabinet, and in-depth study of its nature, so that we have a higher level of variable wind control technology, can better protect the personal safety of our laboratory personnel.

Reference

[1]] Cheng Yong, Liu Dong, Wang Tingting, Wang Kang, Wang Xinlin. The face velocity requirement of laboratory and testing analysis of row [J]. HVAC, 2012,08:84-88.

[2] Zhang Zhanlian, Wan. Effects of laboratory air flow organization on pollutant control [J]. refrigeration and air conditioning, 2014,12:80-84.

Previous post:Study on the design of clean environment control system